In vitro inhalation exposure modules for 12-well inserts

VITROCELL® Exposure Systems have been specifically designed and engineered to facilitate the research of human cell cultures direct exposure to airborne substances such as gases, complex mixtures, nanoparticles and fibers. The system authentically simulates the conditions of human physiological exposure.

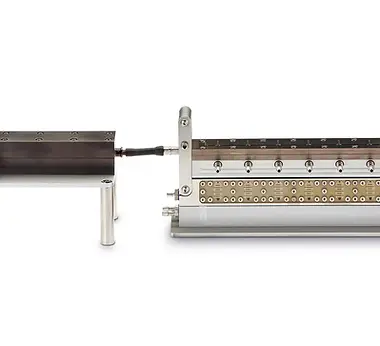

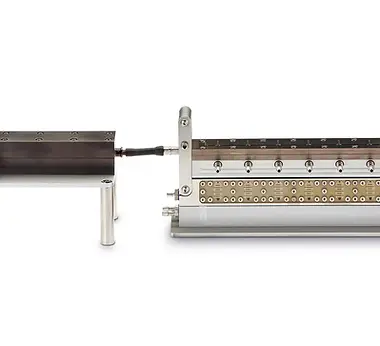

VITROCELL® 12/3 and 12/4 CF Stainless Steel

Stainless Steel modules for 12-well sized inserts

VITROCELL® 12/3 and 12/4 CF

Stainless Steel Exposure Module

The VITROCELL® 12 CF module system has been specifically designed and engineered to facilitate the research of human cell cultures direct exposure to airborne substances such as gases, complex mixtures, nanoparticles and fibers. The system authentically simulates the conditions of human physiological exposure.

VITROCELL® 12/3 and 12/4 CF Base Module

This modules’ casing is made of electropolished stainless steel. It is designed with three or four compartments for 12-well cell culture inserts and is fully autoclavable at 121° C (250° F) for 20 min. Through the employment of a special adapter set, this module can also be flexibly combined for use with 24-well cell culture inserts. A constant unit temperature is guaranteed using a regulated flow of temperature-controlled water through the module.

VITROCELL® 12/3 and 12/4 CF Base Module

The medium can be supplied individually to each well compartment. Flexible medium exchange can be static, intermittent or continuous basis, this flexibility is afforded by use of a precision medium pump. This module is renowned in scientific circles for its reliability and durability.

VITROCELL® 12/3 and 12/4 CF Stainless Steel Aerosol exposure top

The aerosol inlet-stream flows through specially shaped inlets.

3 types of aerosol-inlet materials are available:

-

Stainless Steel

-

Stainless Steel with unique VITROGLIDE surface treatment

The stainless steel / VITROGLIDE inlets are specially designed for aerosols containing nano-range particles. VITROCELL® calibration valves are connected to a vacuum pump to control flow rates effectively. The aerosol exposure top features an in/outlet for heating the water circuit, ensuring corresponding temperatures with the base module. It is made of high-quality anodized aluminum.

VITROCELL® 12/3 and 12/4 CF Stainless Steel Controlled inlet flow

VITROCELL® exposure systems have been specifically designed and engineered to give researchers the possibility of directly exposing mammalian cells or tissue at the air/liquid interface. Thus, all cell types cultivated on microporous membranes can be used. This approach allows for more credible and authentic results than by submerged exposure due to a closer replication of the human physiology.

VITROCELL® 12/3 and 12/4 CF Option for microbalance sensor

The QCM sensor can be integrated in the exposure module. It is capable of measuring the deposited mass in nanogram/cm2 per second. Results are reported online by the VITROCELL® Monitor software. Data is presented in graphs and stored in MS Excel®.

VITROCELL® 12/3 and 12/4 CF Adaptor-Sets

Universal module with optional adaptor sets for:

-

12-well sized inserts

-

24-well sized inserts

All commercial brands are supported.

VITROCELL® 12/3 and 12/4 CF Features

-

Suitable for COSTAR®, FALCON® and ThinCert® 6-well sized cell culture inserts

-

Adaptors for 12 and 24-well sized inserts

-

Individual media inlets and outlets for each cell culture insert compartment

-

Special inlet geometry of the aerosol exposure top for optimal particle deposition

-

Inlets made of stainless steel with a unique VITROGLIDE surface treatment

-

Base module made of electropolished stainless steel

-

Base module and aerosol exposure top with integrated water heating circuit

-

Control window for monitoring culture medium levels

-

Autoclavability of all components

-

Suitable for VITROCELL® Quartz Crystal Microbalance

VITROCELL® 12/6 Stainless Steel

Stainless Steel modules for 12-well sized inserts

VITROCELL® 12/6

Stainless Steel Exposure Module

The VITROCELL® 12/6 module system has been specifically designed and engineered to facilitate the research of human cell cultures direct exposure to airborne substances such as gases, complex mixtures, nanoparticles and fibers. The system authentically simulates the conditions of human physiological exposure.

VITROCELL® 12/6 Base module

stainless steel. They are designed with six compartments for 12-well cell culture inserts and are fully autoclavable at 121° C (250° F) for 20 min. A transparent control window facilitates the external monitoring of media levels. Through the employment of a special adapter set, this module can also be flexibly combined for use with 24-well cell culture inserts. A constant unit temperature is guaranteed using a regulated flow of temperature-controlled water through the module.

VITROCELL®12/6 Aerosol exposure top

Special sealing and connection mechanisms guarantee a hermetic connection of the base module with the aerosol exposure top.

The aerosol inlet-stream flows through specially shaped inlets. The stainless steel / VITROGLIDE inlets are specifically designed for aerosols containing nanoparticles. The aerosol exposure top features an in/outlet for heating the water circuit, ensuring corresponding temperatures with the base module. It is made of high-quality anodized aluminum.

VITROCELL®12/6 Controlled inlet flow

VITROCELL® exposure systems have been specifically designed and engineered to give researchers the possibility of directly exposing mammalian cells or tissue at the air/liquid interface. Thus, all cell types cultivated on microporous membranes can be used. This approach allows for more credible and authentic results than by submerged exposure due to a closer replication of the human physiology.

VITROCELL®12/6 Option for microbalance sensor

The QCM sensor can be integrated in the exposure module. It is capable of measuring the deposited mass in nanogram/cm2 per second. Results are reported online by the VITROCELL® Monitor software. Data is presented in graphs and stored in MS Excel®.

VITROCELL®12/6 Adaptor-Sets

Universal module with optional adaptor sets for:

-

12-well sized inserts

-

24-well sized inserts

All commercial brands are supported.

VITROCELL®12/6 Features

-

Suitable for COSTAR®, FALCON® and ThinCert® 12-well sized cell culture inserts

-

For higher troughput

-

Autoclavability of all components

-

Base modules’ casing made of electropolished stainless steel for extreme durability

-

Base module with water heated base plate

-

Integration of the hyperboloid geometry of inlets into the aerosol exposure top

-

Dynamic dilution system part of delivery

-

Option: Control window for monitoring culture medium levels

VITROCELL® 12/12

For 12 cell culture inserts (12-well size)

VITROCELL® 12/12

The VITROCELL® 12/12 module system has been specifically designed and engineered to facilitate the research of human cell cultures direct exposure to airborne substances such as gases, complex mixtures, nanoparticles and fibers. The system authentically simulates the conditions of human physiological exposure.

VITROCELL® 12/12 Base module

The VITROCELL® 12/12 modules’ casing is made of electropolished stainless steel. It is designed with 12 (4x3) compartments for 12-well cell culture inserts and is fully autoclavable at 121° C (250° F) for 20 min. The capability to expose with up to 4 dilutions or 3 dilutions plus 1 clean-air control in a compact module is its’ outstanding feature. A transparent control window facilitates the external monitoring of media levels. Through the employment of a special adapter set, this module can also be flexibly combined for use with 24-well cell culture inserts. A constant unit temperature is guaranteed using an electronic temperature control.

The medium can be supplied individually for each row of 3 compartments.

VITROCELL® 12/12 Aerosol exposure top with central aerosol supply

Special sealing and connection mechanisms guarantee a hermetic connection of the base module with the aerosol exposure top.

The aerosol inlet-stream flows through specifically shaped inlets. They are available in stainless steel or stainless steel with unique VITROGLIDE surface treatment for lowest adhesion results. The stainless steel / VITROGLIDE inlets are specifically designed for aerosols containing nanoparticles.

The aerosol inlets are connected to the distribution or dilution systems. Extraction from the module takes place via small holes using a controlled vacuum flow. VITROCELL® calibration valves, which are connected to a vacuum pump control flow rates effectively. The aerosol exposure top features an in/outlet for heating the water circuit, ensuring corresponding temperatures with the base module. It is made of high-quality anodized aluminum.

VITROCELL® 12/12 Climatic Chamber

For equal temperature control of all tubings and aerosol ducts. The professional solution to avoid condensation during the exposure to liquid aerosols.

VITROCELL® 12/12 Option for microbalance sensor

The QCM sensor can be integrated in the exposure module. It is capable of measuring the deposited mass in nanogram/cm2 per second. Results are reported online by the VITROCELL® Monitor software. Data is presented in graphs and stored in MS Excel®.

VITROCELL® 12/12 Adaptor-Sets

Universal module with optional adaptor sets for:

-

12-well sized inserts

-

24-well sized inserts

All commercial brands are supported.

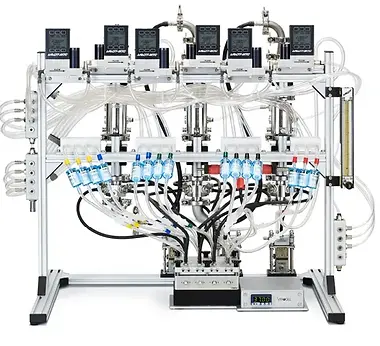

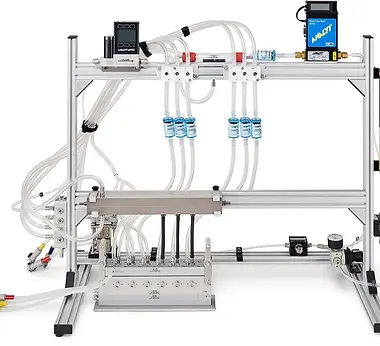

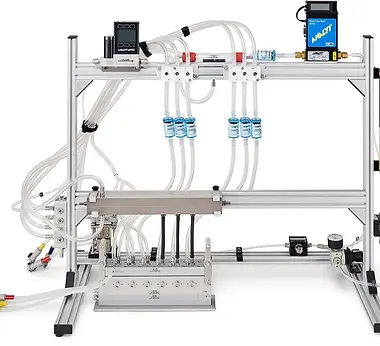

VITROCELL® 12/12 Docking Station

-

A complete rack system for fixation of components features a docking station with sliding base for fast and safe connections. The unique quick-connect system allows for tubeless connections of distribution and distribution systems.

VITROCELL® 12/12 Isokinetic Sampling System

-

The aerosol is guided from the central duct to the modules via isokinetic sampling probes enabling high reproducibility and uniformity of results.

-

The inlets aspirate directly from the constant flow of test substance.The isokinetic distribution system is made of stainless steel.

The optional dilution systems are equipped with air jets for dynamic dilution to obtain different dose / response results per row @ 3 replicates.

VITROCELL® 12/12 Features

-

Suitable for COSTAR®, FALCON® and ThinCert® 12-well sized cell culture inserts

-

Autoclavability of all components

-

Base module made of electropolished stainless steel for extreme durability

-

Electronic heating system

-

Base module and aerosol exposure top with integrated heating circuit

-

Integration of the hyperboloid geometry of inlets into the aerosol exposure top

-

Control window for monitoring culture medium levels

-

The result: optimized particle deposition

VITROCELL® 12/6 CF Stainless Steel

For 6 cell culture inserts (12-well size)

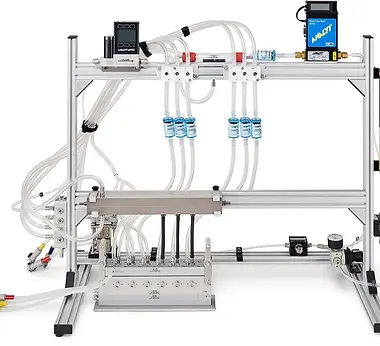

VITROCELL® 12/6 CF

Stainless Steel Exposure Module

The VITROCELL® 12/6 CF module system has been specifically designed and engineered to facilitate the research of human cell cultures in direct exposure to airborne substances such as gases, complex mixtures, nanoparticles and fibers. The system authentically simulates the conditions of human physiological exposure.

Normally 3 compartments are used for exposure to the substances and 3 compartments for clean air control. The capacity can be easily increased by adding more modules. Each module can receive a different dose concentration, so that a complete dose / response profile is obtained in one experiment.

The cells are exposed at the air / liquid interface on 6 cell culture inserts using low flow rates of the aerosol. After exposure, the cells are further processed to measure a wide range of endpoints, e. g. cytotoxicity, genotoxicity, proliferation, cellular and oxidative stress as well as inflammation.

VITROCELL® 12/6 CF Base module

The VITROCELL® 12/6 CF modules’ casing is made of electropolished stainless steel. It is designed with six compartments for 12-well cell culture inserts and is fully autoclavable at 121° C (250° F) for 20 min. A transparent control window facilitates the external monitoring of media levels. Through the employment of a special adapter set, this module can also be flexibly combined for use with 24-well cell culture inserts. A constant unit temperature is guaranteed using a regulated flow of temperature-controlled water through the module.

The medium can be supplied gravimetrically using a bottle or syringe. This module is renowned in scientific circles for its reliability and durability.

VITROCELL ® 12/6 CF Base module

The medium can be supplied gravimetrically using a bottle or syringe. This module is renowned in scientific circles for its reliability and durability.

VITROCELL® 12/6 CF Aerosol exposure top with individual aerosol inlets

Special sealing and connection mechanisms guarantee a hermetic connection of the base module with the aerosol exposure top.

The aerosol inlet-stream flows through specifically shaped inlets. They are available in stainless steel or stainless steel with unique VITROGLIDE surface treatment for lowest adhesion results. The stainless steel / VITROGLIDE inlets are specifically designed for aerosols containing nanoparticles.

The aerosol inlets are connected to the distribution or dilution systems. Extraction from the module takes place via small holes using a controlled vacuum flow. VITROCELL® calibration valves, which are connected to a vacuum pump control flow rates effectively. The aerosol exposure top features an in/outlet for heating the water circuit, ensuring corresponding temperatures with the base module. It is made of high-quality anodized aluminum.

VITROCELL® 12/6 CF System available in different setups for dosimetry

The system can be combined with a separate single module for dosimetry. The dosimetry module can accomodate a stainless steel insert for trapping constituents of the aerosol in liquids. Alternatively it can be equipped with a microbalance sensor.A photometer can be added either directly in the aerosol flow of the Exposure Module or at a seperate port of the main aerosol flow.

VITROCELL® 12/6 CF Option for microbalance sensor

The QCM sensor can be integrated in the exposure module. It is capable of measuring the deposited mass in nanogram/cm2 per second. Results are reported online by the VITROCELL® Monitor software. Data is presented in graphs and stored in MS Excel®.

VITROCELL® 12/6 CF Adaptor-Sets

Universal module with optional adaptor sets for:

-

12-well sized inserts

-

24-well sized inserts

All commercial brands are supported.

VITROCELL® 12/6 CF Features

-

Suitable for COSTAR®, FALCON® and ThinCert® 12-well sized cell culture inserts

-

For higher troughput

-

Autoclavability of all components

-

Base module made of electropolished stainless steel for extreme durability

-

Base module with water heating base plate

-

Hyperboloid geometry of inlets for optimized particle deposition and distribution

-

Option: Quartz Crystal Microbalance

_edited.png)